| |

The A.R.E. System features several innovations

to minimize installation time. The System shaft (4) and coupling (6)

are machined with steeper tapers. This allows easy shaft removal from

the coupling, yet maintains a snug and concentric fit. The shaft is

secured to the coupling with a woodruff key (5) and a flanged retaining

nut (8). A self-locking set screw (7) through the side of the coupling

seats on the flange of the retaining nut, providing a positive lock

that disassembles easily for service. The retaining nut recess of the

coupling is threaded for a Separator (9). The Separator is a jacking

plug which, when threaded into the retaining nut recess with the nut

removed, pushes the shaft out of the coupling.

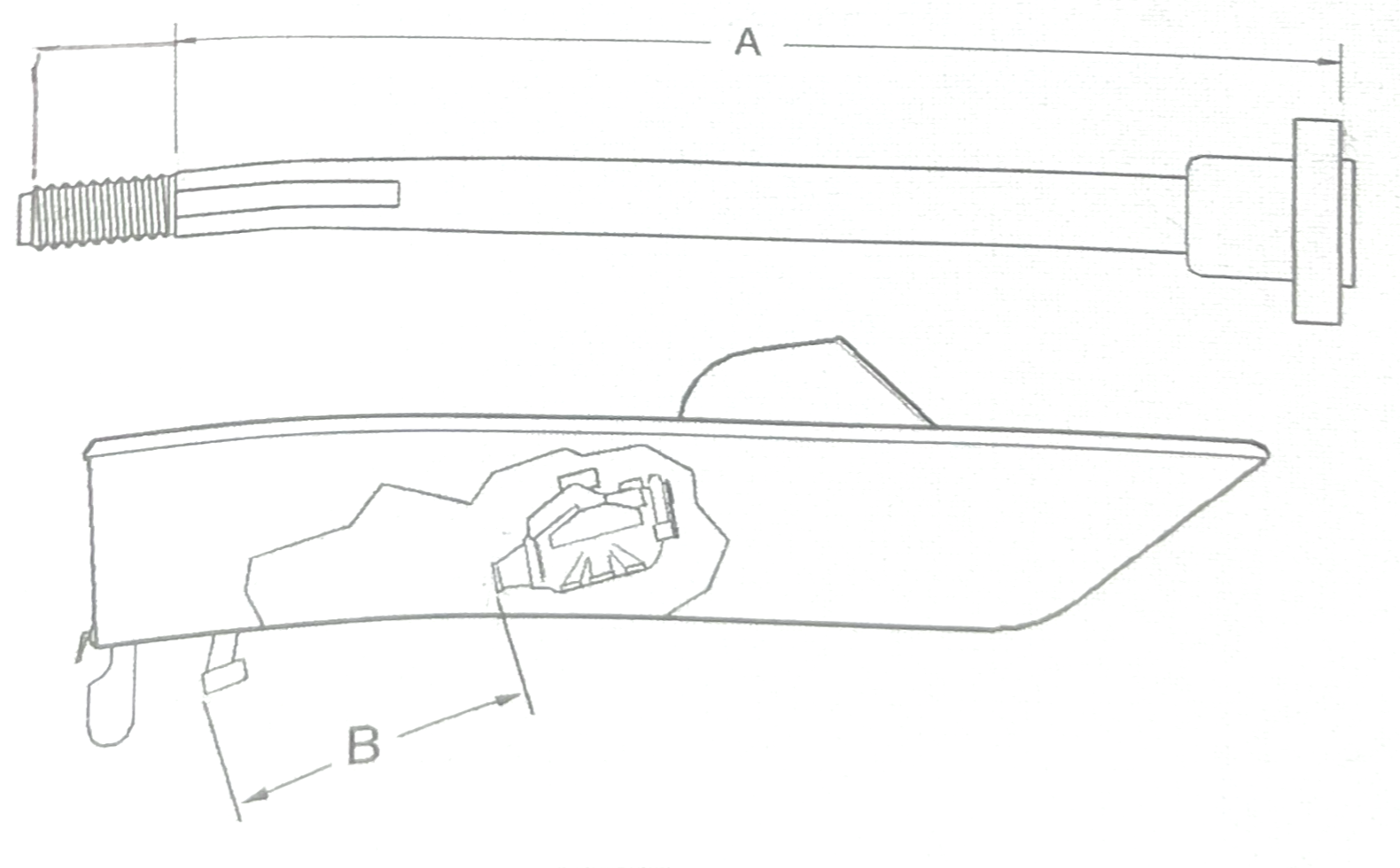

Also available are specialized tools for drive

shaft maintenance. The offset prop wrench (D) fits the prop nut and the

Ironman prop puller. The Ironman prop puller (C) removes 3-blade and

4-blade propellers quickly and efficiently. The coupling wrench (B)

prevents the shaft assembly from turning when removing the retaining

nut. The System socket (A) is used to remove the retaining nut, and

will work on boats with as little as 1” clearance between the coupling

face and the transmission flange.

|

|

|

Ordering Information & Directions

Please specify the model and year of the boat and the grade, length,

and diameter of the shaft when ordering drive shafts. If one or more of

these specifications is unknown, the following information may be of

help.

There are three grades of shafting, 17, 19, and 22. Grade 17 material

is the least corrosion resistant of the grades. It is a good choice for

boats used primarily in freshwater. Grade 19 material is better suited

for salt-water as it has better corrosion resistance than 17. Boats

that sit idle in saltwater for extended periods of time should consider

Grade 22. It has the highest corrosion resistance. Typically, Grade 22

shafting is also stronger than 17 or 19.

Elbert's has extensive records on drive shaft lengths for many boats.

Often, we can supply the correct shaft length with only the year, make

and model of the boat. However, boat manufacturers sometimes change

shaft lengths during the model year. This, along with other factors,

can make determining shaft length from year, make, and model of the

boat less than 100% reliable. To ensure you will receive the correct

shaft length please supply us with either dimension A or dimension B

from Figure 9-1.

The diameter of the shaft, if unknown, is easily determined by measuring with calipers or a tape measure.

|